In the era of hyper-connected data and automation, the backbone of reliable signal and power transmission lies within advanced cable manufacturing. The demand for higher frequencies, greater bandwidth, and unwavering consistency in cables for data centers, robotics, and automotive systems directly translates to a critical need for extreme precision in the core shielding and insulating processes. At the heart of this precision manufacturing is the Numerical Control Horizontal Multi-Layer Taping Machine, a technological leap that addresses the industry's stringent requirements for stability, speed, and flawless quality.

Foundational Knowledge: The Role of Taping in Cable Manufacturing

Taping is a fundamental process where thin, flat materials (like mylar, aluminum foil, or composite tapes) are helically or longitudinally wrapped around a conductor or cable core. This serves key functions:

-

Shielding: Isolates signals from electromagnetic interference (EMI).

-

Insulation: Provides electrical separation.

-

Moisture/Barrier Protection: Shields against environmental factors.

-

Cushioning/Binding: Protects internal components and holds strands together.

The evolution from mechanical to Computer Numerical Control (CNC) taping represents a paradigm shift, enabling programmable, repeatable, and highly stable production essential for modern high-frequency cables.

Traditional vs. Modern CNC Taping Approach

| Aspect |

Traditional Taping |

Modern CNC Taping |

| Control System |

Mechanical, Cam-based |

Computer Numerical Control (PLC/Servo) |

| Tension Control |

Passive, friction-based; varies with tape roll diameter |

Active, Servo-controlled; constant tension regardless of roll status |

| Precision & Repeatability |

Lower, prone to human error |

High, digitally set and maintained |

| Flexibility |

Low, changeovers are slow |

High, parameters changed via touchscreen |

| Suitability |

Standard cables |

High-frequency, high-speed data cables (HDMI, SFP, DP, etc.) |

Core Technical Pillars: Industry Metrics Addressed by Advanced Taping

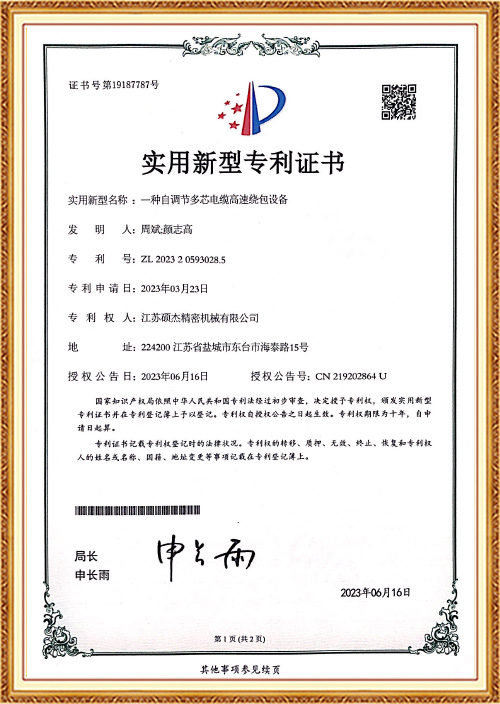

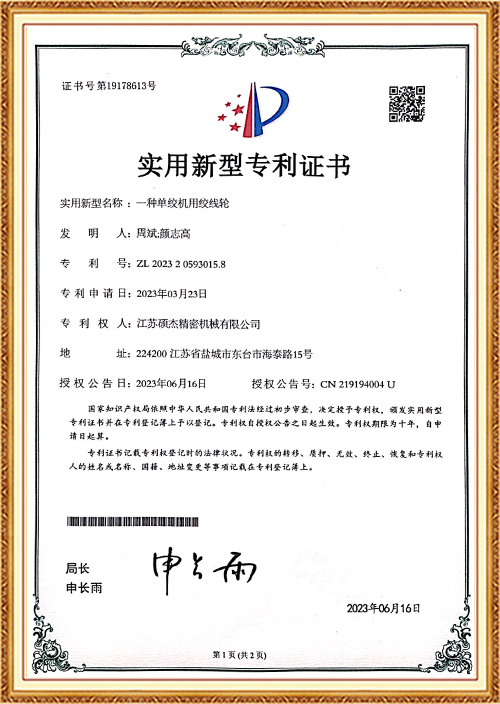

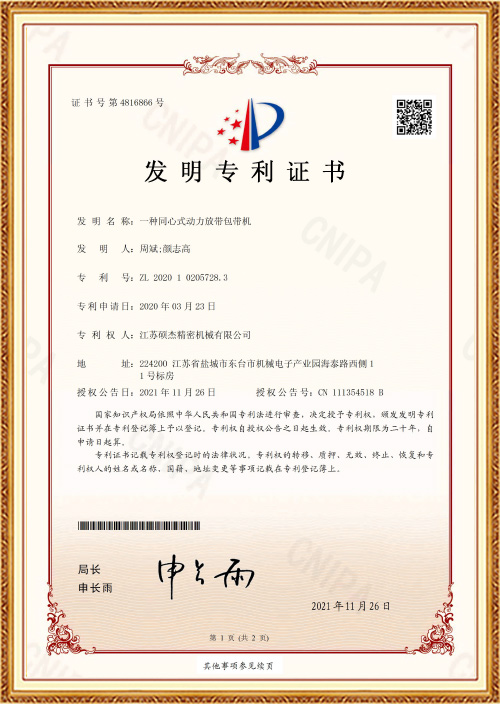

The performance of a taping machine is evaluated against specific industry metrics. Jiangsu Newtopp Precision Machinery's design directly targets and optimizes these critical parameters.

-

Tension Stability & Consistency: Variable tension causes gaps, wrinkles, or overlaps in the tape, leading to signal integrity issues. Our active tape pay-off system with servo torque control ensures truly constant tension. This eliminates the "full to empty" roll tension variation, a common flaw in traditional systems, guaranteeing uniform wrap quality from start to finish.

-

Wrapping Precision (Pitch Accuracy): The consistency of the wrap overlap is paramount. Our machines feature PLC-controlled pitch setting via touchscreen, ensuring the wrapping point remains steady during normal operation, acceleration, and deceleration. This results in a perfectly uniform layer.

-

Traversing & Layering Quality: For multi-layer applications, precise and clean traversing is essential to prevent stacking errors. The axis-row type take-up traversing structure allows for arbitrarily set spacing, enabling flawless parallel or multi-layer wraps, which is critical for complex cable designs.

-

Output & Yield Rate: Productivity cannot compromise quality. With a high-rotation-speed design delivering up to 2.5 times the work rate of traditional machines, Newtopp's tapers achieve high output while maintaining a 100% pass rate for demanding applications like HDMI, SFP, QSFP, and SAS cables. This synergy of speed and accuracy is a key industry differentiator.

How Newtopp's Technology Solves Industry Challenges

| Industry Challenge |

Conventional Limitation |

Newtopp CNC Horizontal Taping Machine Solution |

| Unstable Tension |

Spring/brake systems; tension drops as spool depletes |

Servo Torque Mode & Active Pay-off: Direct tension value input; real-time auto-adjustment. |

| Longitudinal Wrap Instability |

Lateral offset angle causes uneven tension on tape edges. |

Dynamic Shaft Traversing Structure: Eliminates offset angle, ensuring stable straight wrapping. |

| Inconsistent Pitch During Speed Changes |

Mechanical slippage leads to uneven wrap spacing. |

PLC & Servo Synchronization: Maintains precise pitch control throughout acceleration/deceleration cycles. |

| Low Efficiency |

Limited spindle speed and manual interventions. |

High-Speed Spindle Design: Engineered for 2.5x higher output without sacrificing precision. |

The cable industry is moving towards:

Higher Frequencies & Data Rates: Demanding even tighter tolerances in shielding integrity.

Miniaturization: Requiring machines capable of handling finer conductors with extreme precision.

Automation & Industry 4.0: Machines must integrate into smart factories with data collection and remote monitoring capabilities.

Sustainable Manufacturing: Emphasis on reducing waste (from defects) and energy-efficient operation.

Newtopp's Numerical Control Horizontal Multi-Layer Taping Machine is engineered for these trends. Its digital core allows for seamless integration into automated lines. The guaranteed 100% pass rate for premium cables directly reduces material waste. Furthermore, as a National High-Tech Enterprise with a dedicated R&D center, Newtopp continuously innovates, ensuring our equipment evolves with your future needs.

Frequently Asked Questions (FAQs)

Q1: What types of wrapping materials can your machine handle?

A: Our machines are designed for a wide range of materials including aluminum foil, mylar/polyester tape, copper tape, composite tapes (e.g., Al-Mylar), and various paper or non-woven materials used for insulation and cushioning.

Q2: How does the "active pay-off" system actually maintain constant tension?

A: Unlike passive brakes, our system uses a servo motor in torque control mode to actively pull back against the tape being unwound. The PLC constantly monitors and adjusts the servo's torque output based on the set tension value, compensating in real-time for changes in spool diameter, inertia, and speed.

Q3: Can your taping machine integrate with our existing downstream equipment?

A: Yes. As a provider of a full range of cable equipment (from stranding to extruding), we design for interoperability. Our CNC tapers have standard PLC interfaces (e.g., Ethernet/IP, Profinet) and can be synchronized with capstans, dancers, or other line components for seamless integration.

Q4: What is the minimum or maximum cable core diameter you can accommodate?

A: Specific capacities depend on the model. Our product range includes configurations for fine coaxial cores used in data cables to larger power cable cores. Please consult with our engineering team for your specific diameter and lay length requirements.

English

English русский

русский Español

Español