The Horizontal/Vertical Type Back-Twist+Pair Stranding Machine is a pivotal piece of equipment in high-end data cable manufacturing. It is specifically designed for the back-twist pay-off and bare-twist pair stranding of insulated core wires used in precision data cables such as Cat-5, Cat-5e, Cat-6, and HDMI 2.1. The core of this machine lies in its synergistic "back-twist first, then pair-twist" operational mode, which effectively reduces wire stress and damage during the stranding process. This ensures the stability and consistency of the electrical performance of the wire pairs, forming the foundation for producing high-performance, low-latency data transmission cables.

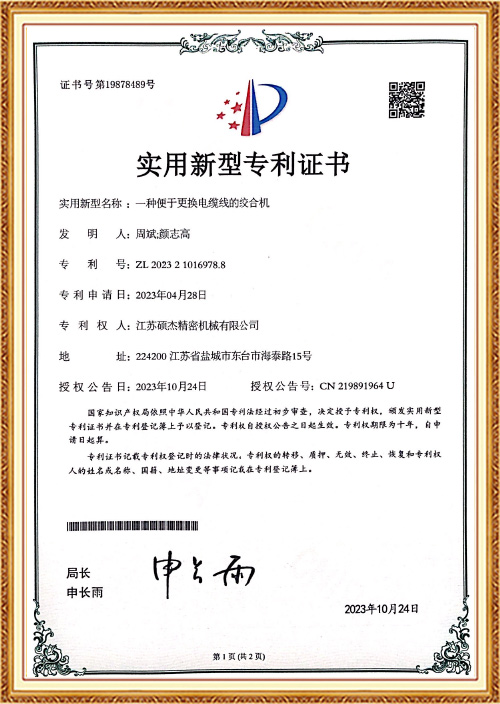

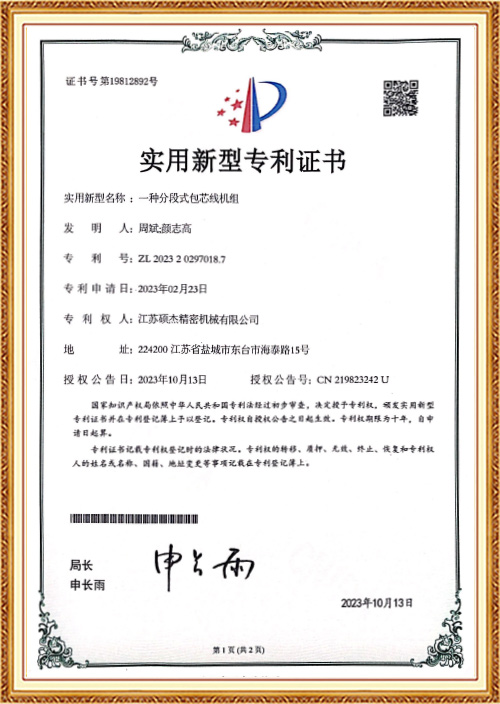

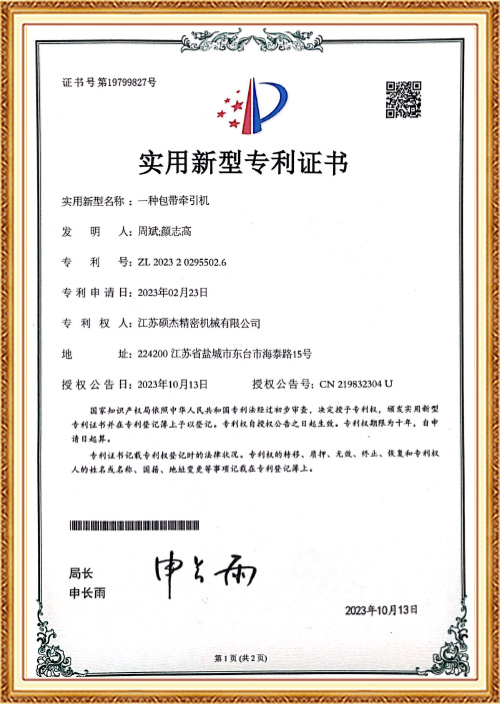

As a key component within the cable equipment product matrix of Jiangsu Newtopp Precision Machinery Co., Ltd., this Back-Twist+Pair Stranding Machine incorporates over a decade of R&D experience in the field of high-precision machinery manufacturing, reflecting our consistent pursuit of the engineering philosophy of "precision, efficiency, and reliability."

In-Depth Technical Principle Analysis

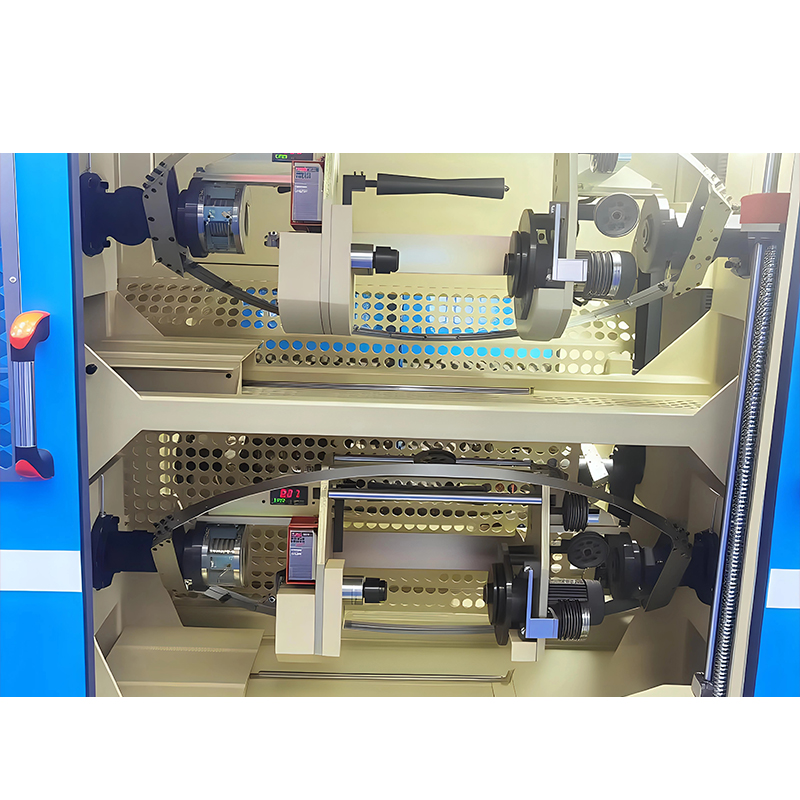

The equipment operates through the coordinated work of a Φ500 active back-twist pay-off machine and a Φ500 pair stranding machine. Its core principle is that the active back-twist pay-off unit neutralizes the inherent torsion of the core wire generated during the unwinding rotation in real-time, placing the core wire in a state of "zero torsion" or minimal residual stress before it enters the stranding unit. Subsequently, the pair stranding machine twists two core wires into a pair with high-precision pitch control.

This process minimizes issues such as micro-damage to the insulation layer and changes in conductor elongation rate caused by torque accumulation in traditional pair stranding, significantly improving key electrical performance parameters of the wire pair, including Return Loss and Near-End Crosstalk (NEXT).

Typical Application Cases

| Cable Type |

Application Description |

Performance Requirement for the Back-Twist+Pair Stranding Machine |

| Cat-6/6A |

Gigabit/10-Gigabit Ethernet |

Requires extremely high stranding precision and consistency to guarantee transmission performance at frequencies of 250MHz and above. The back-twist process reduces defects, ensuring channel compliance. |

| HDMI 2.1 |

Ultra-High-Definition Audio-Video Transmission |

Supports high speeds up to 48Gbps, demanding stringent pair symmetry and signal integrity. The equipment ensures uniform pair stranding and low damage. |

| Specialized High-Speed Data Cables |

Data Center, Server Internal Connections |

Often must meet stricter impedance and attenuation requirements. The machine's stability and high precision guarantee the batch production of qualified products. |

Leveraging the R&D strength of a National High-Tech Enterprise, Newtopp Precision designs the Back-Twist+Pair Stranding Machine to fully meet the stringent requirements of the aforementioned high-end applications for fundamental wire manufacturing.

Maintenance and Technical Support

To ensure the Horizontal/Vertical Type Back-Twist+Pair Stranding Machine maintains optimal accuracy and stability over the long term, Newtopp recommends adhering to the following maintenance guidelines:

-

Daily Inspection: Check pneumatic component pressure, tension system response, main bearing temperature rise, and any abnormal vibration.

-

Regular Maintenance: Replenish specified grease for rotating components (e.g., back-twist bearings, stranding bow bearings) according to schedule, clean photoelectric sensors, and inspect and tighten all electrical connections.

-

Accuracy Calibration: Periodically calibrate the back-twist angle and stranding pitch using professional instruments. This service can be provided by Newtopp's professional engineers.

Newtopp Precision ensures the quality of every machine delivered through its ISO9001 Quality Management System. Supported by a full-chain service system covering R&D, manufacturing, and sales, we provide customers with comprehensive support ranging from installation and commissioning, operator training, to lifelong technical assistance.

Frequently Asked Questions (FAQ)

-

Q: Why is the "back-twist" step necessary in manufacturing data cable pairs?

A: Back-twisting is employed to eliminate the rotational stress accumulated in the insulated core wire during the pay-off process. Without back-twisting, direct pair stranding would cause this stress to lead to micro-deformation of the wire's internal structure, severely impacting the stability of characteristic impedance and crosstalk indicators during high-frequency signal transmission. This makes it difficult for the cable to pass high-standard tests such as Cat-6/HDMI 2.1.

-

Q: What are the specific advantages of Newtopp's Back-Twist+Pair Stranding Machine compared to ordinary pair twinners?

A: The core advantage is the integrated synergy of "active back-twist" and "high-precision pair stranding." Ordinary pair twinners lack back-twist or have only simple over-twist compensation, which can easily cause wire damage. Our equipment achieves active back-twisting through a precision control system, protecting the wire from the source. Simultaneously, the stranding unit, with its high-rigidity design and advanced drives, ensures extremely uniform and consistent lay length. This directly enhances the first-pass yield rate of the product's electrical performance and overall production yield.

-

Q: What are the main factors to consider when choosing between the Horizontal and Vertical types?

A: The primary consideration is the spatial layout of the workshop (elongated or tall space). Secondly, consider operational and maintenance habits. The horizontal type facilitates operation and is suitable for most traditional workshops. The vertical type saves floor space and is ideal for modern production lines with high automation and compact layouts. Newtopp sales engineers can provide optimal selection recommendations based on your specific floor plan.

-

Q: Can the equipment accommodate the production of core wires with different specifications (e.g., diameter, lay length)?

A: Yes. Newtopp's Back-Twist+Pair Stranding Machine is designed for good versatility. Production can be quickly switched between different wire pair specifications by changing the pay-off spool, adjusting the tensioner, and modifying stranding parameters (such as speed, pitch, etc.) on the touchscreen. We provide detailed operation manuals and parameter setting guidance.

-

Q: As the equipment manufacturer, how does Newtopp ensure the long-term stable operation of the machine?

A: Firstly, core components such as the main spindle, bearings, and servo systems are sourced from internationally renowned brands. Secondly, we possess an independent R&D center and finishing center, allowing for in-house precision machining of key structural parts to ensure foundational quality. Finally, we provide comprehensive after-sales support, including remote diagnostics, spare parts supply, and regular follow-ups, ensuring our customers' production lines operate continuously and efficiently. Our ISO14001 Environmental Management System also commits us to practicing environmental responsibility in equipment manufacturing and service.

English

English русский

русский Español

Español