Cable Stranding Machine Supplier

Cable Stranding Machine is a key piece of equipment in the wire and cable manufacturing industry, designed to combine multiple wires or conductors into a single, cohesive strand. This machine is widely used across various types of cable production, including power cables, communication cables, and specialty cables, providing consistent twisting and precise alignment of individual wires. The core functions of a Cable Stranding Machine include controlling the twisting tension, synchronizing rotation speeds, and maintaining uniform strand geometry, which are essential for ensuring product reliability and electrical performance. Modern cable stranding machines feature high-efficiency drive systems, advanced tension control mechanisms, and modular designs that allow easy adjustment for different wire sizes and strand configurations. These machines contribute to optimized production efficiency, reduced material waste, and improved cable quality. By integrating a Cable Stranding Machine into a cable manufacturing line, manufacturers can achieve stable performance, high precision, and adaptability for diverse production requirements.

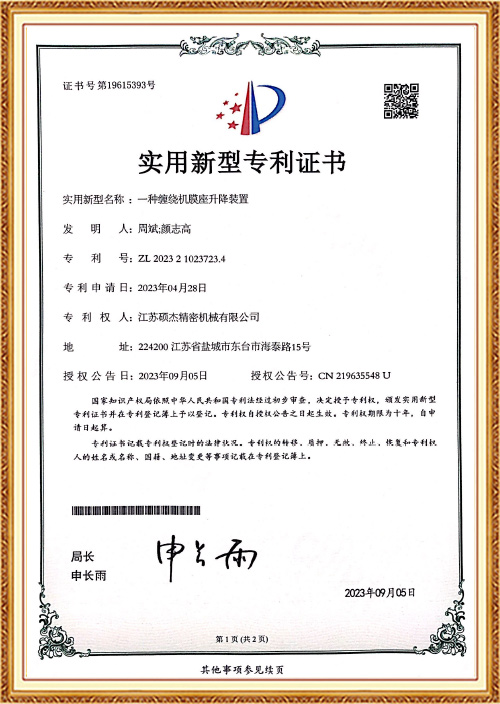

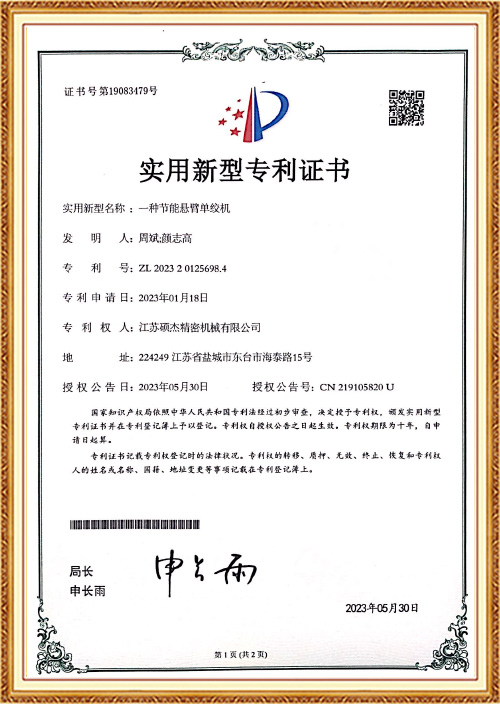

Newtopp Precision is a National High-Tech Enterprise and has obtained ISO9001 quality certification and ISO14001 environmental management system certification. Covering 50 acres, the company boasts an independent R&D center, a finishing center, and a paint booth, integrating R&D, design, manufacturing, and sales. We are committed to providing customers with high-quality products and excellent service.

As a professional cable stranding machine supplier and high speed twisting machine company, Our company's sustainable development along the way is inseparable from the support and trust of our customers. The large enterprises have long-term cooperation with many customers from all walks of life.

-

What Are the Key Features of a Cable Stranding Machine?A cable stranding machine is a crucial piece of equipment in the manufacturing process of cables, us...

-

What industries commonly utilize Cable Stranding Machines for production?Cable Stranding Machines are essential equipment in modern wire and cable manufacturing. These machi...

-

What types of cable stranding machines are there?Cable Stranding Machines play a vital role in the manufacturing of electrical cables, telecommunicat...

-

What is a Cable Stranding Machine and What is Its Primary Function?The manufacturing of electrical cables and wires involves numerous specialized processes, and one of...

-

How does a Cable Stranding Machine work in the stranding process?A Cable Stranding Machine is a critical piece of equipment in the cable manufacturing industry, resp...

A Cable Stranding Machine is a core piece of equipment in the wire and cable manufacturing process, designed to twist multiple single wires or conductors into a unified stranded structure with a defined lay length and direction. This equipment is widely used in the production of power cables, communication cables, data transmission cables, automotive cables, new energy cables, and industrial specialty cables. By precisely controlling stranding pitch, tension, and rotational stability, the Cable Stranding Machine ensures conductor consistency, mechanical strength, and stable electrical performance.

In modern cable production lines, a Cable Stranding Machine not only shapes the conductor but also directly influences cable flexibility, fatigue resistance, current-carrying capacity, and the stability of subsequent processes such as extrusion, taping, and cabling.

Common Functions and Characteristics of Cable Stranding Machines

Although different models vary in structure and configuration, all Cable Stranding Machines share several key characteristics:

-

Unified purpose: Stranding copper, aluminum, or alloy conductors

-

Core functionality: Accurate control of lay length, stranding direction, and conductor geometry

-

Performance focus: High stranding precision, stable operation, and consistent tension control

-

High system integration: Coordinated operation with pay-off stands, capstans, and take-up systems

-

Wide industry applicability: Suitable for power, communication, automotive, and new energy cable production

Working Principle of a Cable Stranding Machine

The working principle of a Cable Stranding Machine is based on controlled rotational motion. Multiple individual wires are fed from pay-off units and twisted around a central axis through a rotating cage, tube, drum, or cantilever structure. The take-up speed and rotational speed are synchronized to achieve the required stranding pitch.

Key operational elements include:

-

Rotating components generating the stranding motion

-

Stable wire supply from pay-off systems

-

Tension control mechanisms ensuring uniform stress on each wire

-

Take-up units maintaining the final conductor structure

This principle applies to single stranding, multi-layer stranding, and back-twist stranding processes.

Main Types of Cable Stranding Machines

| Machine Type | Working Method | Suitable Conductors | Typical Applications |

|---|---|---|---|

| Cage-type Planetary Stranding Machine | Planetary rotation | Large cross-section copper/aluminum | Power and energy cables |

| Tubular Stranding Machine | High-speed tube rotation | Small cross-section conductors | Communication and control cables |

| Drum Twister | Rotating drum stranding | Multi-layer stranded conductors | Medium and high-voltage cables |

| Cantilever Single Twister | Cantilever single stranding | Single-layer or paired conductors | Data cables, automotive cables |

| Back-twist Twinning Machine | Back-twist stranding | Paired conductors | Network and signal cables |

| Copper Wire Stranding Machine | Dedicated conductor stranding | Bare or tinned copper | Flexible conductors |

Jiangsu Newtopp Precision Machinery Co., Ltd. provides a comprehensive range of stranding equipment, allowing flexible configuration based on conductor size, cable structure, and production capacity requirements.

Typical Application Scenarios

-

Automotive cable manufacturing: Flexible stranded conductors with improved vibration resistance

-

Data and communication cables: Pair stranding to ensure signal consistency

-

New energy cables: Multi-strand structures supporting high current and flexibility

-

Industrial control cables: Stable lay length for compatibility with taping and extrusion processes

In many production lines, Cable Stranding Machines operate in combination with extrusion lines and taping machines to form continuous manufacturing systems.

Comparison with Other Twisting Equipment

| Comparison Item | Cable Stranding Machine | Twisting Machine |

|---|---|---|

| Primary function | Conductor stranding | Pair twisting or cabling |

| Structural complexity | Higher | Lower |

| Production stage | Conductor manufacturing | Cabling or signal structuring |

| Precision requirement | High | Medium |

Cable Stranding Machines focus on conductor formation rather than final cable assembly.

Frequently Asked Questions (FAQ)

Q1: Can a Cable Stranding Machine handle multiple conductor sizes?

A: Yes. By adjusting tooling, stranding cages, and process parameters, different wire diameters can be accommodated.

Q2: How is stranding pitch controlled?

A: Through synchronized control of rotational speed and line speed.

Q3: Can the machine be integrated with extrusion lines?

A: Most models support inline operation with extrusion and taping equipment.

Q4: What factors should be considered when selecting a machine?

A: Conductor material, diameter range, required lay length, production speed, and downstream processes.

English

English русский

русский Español

Español