Wire And Cable Taping Machine Supplier

Cable Taping Machine is a specialized equipment designed for the electrical and cable manufacturing industry, primarily used for wrapping insulating or protective tape around various types of cables. This category of machines focuses on precise tape application, uniform coverage, and high-speed operation, ensuring consistent insulation and protection of cable cores. Cable Taping Machines are commonly employed in both single-core and multi-core cable production lines, integrating seamlessly with extrusion, stranding, and sheathing processes. Key features of this category include adjustable tension control, automatic feeding systems, and compatibility with different tape materials, which allow manufacturers to meet diverse production standards. By using a Cable Taping Machine, companies can enhance production efficiency, maintain product quality, and achieve reliable cable insulation across a wide range of applications.

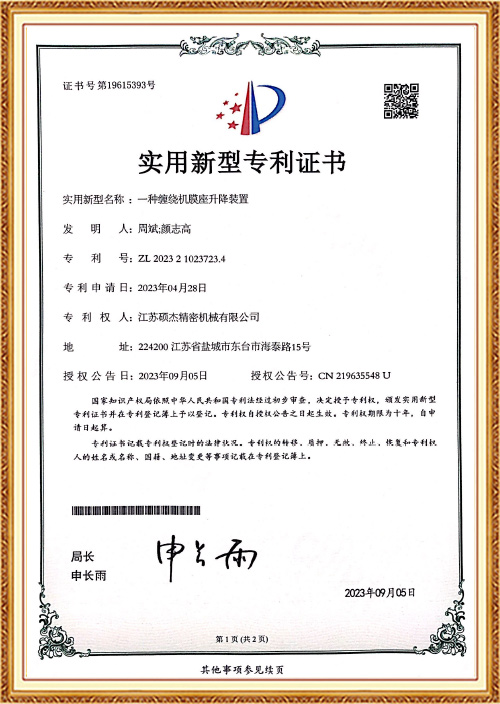

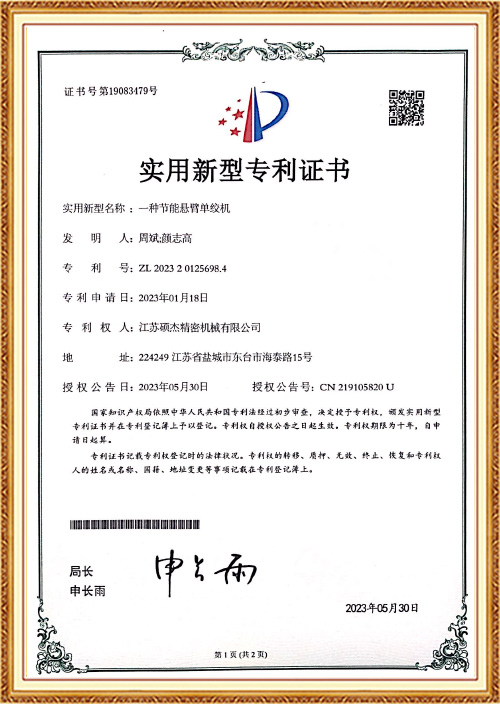

Newtopp Precision is a National High-Tech Enterprise and has obtained ISO9001 quality certification and ISO14001 environmental management system certification. Covering 50 acres, the company boasts an independent R&D center, a finishing center, and a paint booth, integrating R&D, design, manufacturing, and sales. We are committed to providing customers with high-quality products and excellent service.

As a professional wire and cable taping machine supplier and wire and cable taping machine company, Our company's sustainable development along the way is inseparable from the support and trust of our customers. The large enterprises have long-term cooperation with many customers from all walks of life.

-

What Are the Key Features of a Cable Stranding Machine?A cable stranding machine is a crucial piece of equipment in the manufacturing process of cables, us...

-

What industries commonly utilize Cable Stranding Machines for production?Cable Stranding Machines are essential equipment in modern wire and cable manufacturing. These machi...

-

What types of cable stranding machines are there?Cable Stranding Machines play a vital role in the manufacturing of electrical cables, telecommunicat...

-

What is a Cable Stranding Machine and What is Its Primary Function?The manufacturing of electrical cables and wires involves numerous specialized processes, and one of...

-

How does a Cable Stranding Machine work in the stranding process?A Cable Stranding Machine is a critical piece of equipment in the cable manufacturing industry, resp...

A Cable Taping Machine is a critical piece of equipment in cable manufacturing lines, designed to apply one or multiple layers of tape around cable cores, conductors, or insulated wires in a uniform and controlled manner. This category of equipment is widely used to enhance cable structure integrity, improve electrical insulation performance, provide shielding or separation, and support subsequent extrusion or jacketing processes.

Across different models, Cable Taping Machine products share common characteristics in application purpose, mechanical structure, control logic, and performance requirements, making them an essential intermediate process between stranding and extrusion in modern cable production lines.

In cable factories producing data cables, industrial cables, automotive cables, power cables, and new energy cables, Cable Taping Machine systems are commonly configured to meet specific tape materials, taping angles, and line speed requirements. Jiangsu Newtopp Precision Machinery Co., Ltd. has accumulated long-term engineering experience in this field, enabling the integration of taping equipment with upstream stranding machines and downstream extrusion lines in a stable and efficient manner.

Core Functions and Typical Uses of Cable Taping Machines

Cable taping equipment within this category is primarily used to achieve the following functions:

-

Apply insulation tape, polyester tape, mica tape, PTFE tape, or aluminum-plastic composite tape

-

Provide electrical insulation reinforcement

-

Improve mechanical protection and shape stability

-

Create separation layers between conductors and shielding

-

Support EMI shielding and flame-retardant structures

Typical cable types using taping processes include:

-

Data transmission cables

-

Industrial control cables

-

Robotic and flexible motion cables

-

Automotive wire and cable

-

Power and new energy cables

Working Principle of Cable Taping Machines

The basic working principle of a Cable Taping Machine is consistent across different designs:

-

Cable Feeding: The cable core or insulated conductor enters the taping zone under constant tension control.

-

Tape Pay-off and Guidance: Tape reels are mounted on rotating or planetary heads, guided precisely toward the cable surface.

-

Helical or Longitudinal Wrapping: Tape is applied at a defined overlap ratio and taping angle through synchronized rotation and line speed.

-

Tension and Overlap Control: Mechanical or servo-driven systems maintain consistent tape tension and coverage.

-

Exit and Integration: The taped cable is guided toward take-up, extrusion, or other downstream processes.

Advanced Cable Taping Machine models supplied by Jiangsu Newtopp Precision Machinery Co., Ltd. are commonly designed with CNC control systems to ensure stable taping accuracy at different production speeds.

Main Types of Cable Taping Machines

Different production requirements result in multiple types of taping equipment. The table below summarizes common configurations within this category:

| Type of Cable Taping Machine | Structural Characteristics | Typical Applications |

|---|---|---|

| CNC Vertical Taping Machine | Compact vertical layout, precise CNC control | Data cables, automotive wires |

| CNC Horizontal Taping Machine | Stable horizontal structure, suitable for heavy cables | Power cables, industrial cables |

| Single-Layer Taping Machine | One tape head, simple structure | Basic insulation or separation layers |

| Double-Layer Taping Machine | Two synchronized tape heads | Shielding + insulation structures |

| Multi-Layer Taping Machine | Multiple tape heads, high integration | Complex cable constructions |

These configurations allow manufacturers to select equipment based on cable diameter, taping material, production speed, and line integration needs.

Key Performance Characteristics

Although designs may vary, Cable Taping Machine products within this category typically focus on the following performance indicators:

-

Stable tape tension control

-

Accurate overlap and taping angle adjustment

-

Compatibility with multiple tape materials

-

High-speed operation with low tape breakage

-

Easy integration with stranding and extrusion lines

Newtopp Precision leverages its experience in high-end cable equipment to align taping machine performance with overall production line stability rather than isolated machine operation.

Cable Taping Machine vs. Other Cable Processing Equipment

To help users better understand the role of taping machines, the following comparison highlights functional differences:

| Equipment Type | Main Function | Position in Production Line |

|---|---|---|

| Cable Stranding Machine | Twist conductors together | Upstream |

| Cable Taping Machine | Apply insulation or shielding tape | Middle |

| Cable Extrusion Line | Extrude insulation or jacket | Downstream |

This comparison shows that Cable Taping Machine systems act as a structural and functional transition between conductor formation and final insulation or sheathing.

Typical Application Scenarios

Practical application examples include:

-

Automotive cables: Polyester or non-woven tape used for abrasion resistance before jacketing

-

Data cables: Longitudinal or helical taping to maintain pair geometry

-

Power cables: Mica tape wrapping for fire resistance

-

Robotic cables: Multi-layer taping for flexibility and mechanical protection

These cases reflect common production scenarios supported by Jiangsu Newtopp Precision Machinery Co., Ltd. equipment solutions.

Frequently Asked Questions (FAQ)

Q1: What tape materials can a Cable Taping Machine handle?

A: Common materials include polyester tape, PTFE tape, mica tape, aluminum-plastic composite tape, and non-woven fabrics.

Q2: How is taping overlap controlled?

A: Overlap is controlled through synchronized rotation speed and line speed, typically managed by CNC or servo systems.

Q3: Can taping machines be connected to existing production lines?

A: Yes. Most designs support integration with stranding machines and extrusion lines through standardized interfaces.

Q4: How do I choose between single-layer and multi-layer taping machines?

A: The choice depends on cable structure complexity, required insulation performance, and production efficiency goals.

English

English русский

русский Español

Español