Cable Extrusion Line Supplier

Cable Extrusion Line is a specialized production system widely used in the manufacturing of electrical wires and cables. This line integrates multiple processes, including extrusion, cooling, and sizing, to produce insulated cables with consistent quality and precise dimensions. Cable Extrusion Line products are designed to handle various cable types, including power cables, communication cables, and control wires, making them suitable for diverse industrial applications. Key features of this category include high production efficiency, uniform insulation thickness, and compatibility with different raw materials such as PVC, PE, and XLPE. By streamlining the extrusion process and ensuring accurate control over cable dimensions, the Cable Extrusion Line supports continuous production, reduces material waste, and maintains the electrical performance of the finished cables.

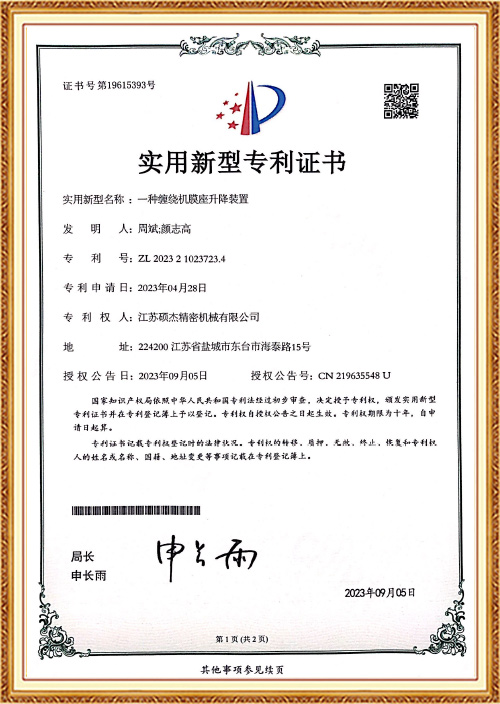

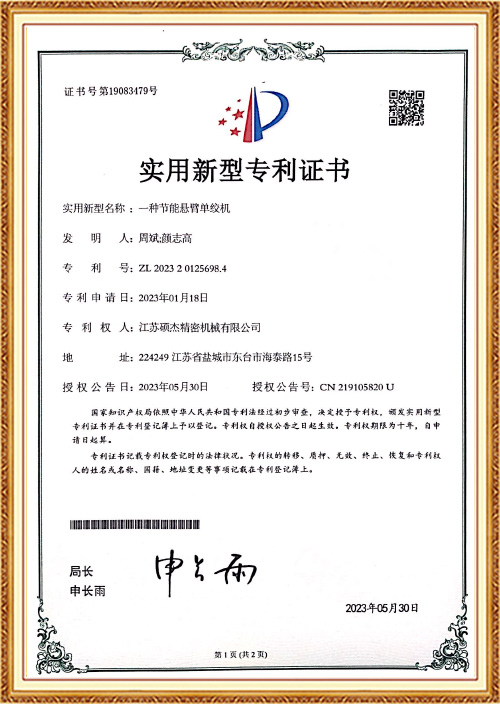

Newtopp Precision is a National High-Tech Enterprise and has obtained ISO9001 quality certification and ISO14001 environmental management system certification. Covering 50 acres, the company boasts an independent R&D center, a finishing center, and a paint booth, integrating R&D, design, manufacturing, and sales. We are committed to providing customers with high-quality products and excellent service.

As a professional cable extrusion line supplier and wire and cable extruder company, Our company's sustainable development along the way is inseparable from the support and trust of our customers. The large enterprises have long-term cooperation with many customers from all walks of life.

-

What Are the Key Features of a Cable Stranding Machine?A cable stranding machine is a crucial piece of equipment in the manufacturing process of cables, us...

-

What industries commonly utilize Cable Stranding Machines for production?Cable Stranding Machines are essential equipment in modern wire and cable manufacturing. These machi...

-

What types of cable stranding machines are there?Cable Stranding Machines play a vital role in the manufacturing of electrical cables, telecommunicat...

-

What is a Cable Stranding Machine and What is Its Primary Function?The manufacturing of electrical cables and wires involves numerous specialized processes, and one of...

-

How does a Cable Stranding Machine work in the stranding process?A Cable Stranding Machine is a critical piece of equipment in the cable manufacturing industry, resp...

A Cable Extrusion Line is a core production system in the wire and cable manufacturing industry, designed to apply insulation layers, inner sheaths, or outer jackets uniformly onto conductors or stranded cores. Within this category, all Cable Extrusion Line products share common objectives: precise material extrusion, stable dimensional control, continuous production, and compatibility with a wide range of cable structures and polymer materials.

In modern cable factories, the Cable Extrusion Line plays a decisive role in determining cable performance, safety compliance, and production efficiency. Whether used for power cables, data transmission cables, automotive cables, or new energy cables, a Cable Extrusion Line integrates extrusion, cooling, diameter control, traction, and take-up into a coordinated system. On this page, Cable Extrusion Line appears as a unified category representing solutions for insulation extrusion, sheath extrusion, and special material extrusion processes.

Jiangsu Newtopp Precision Machinery Co., Ltd. has been involved in the long-term development and manufacturing of Cable Extrusion Line systems since 2004. Based on extensive engineering experience in cable equipment, Newtopp integrates extrusion technology with upstream stranding and taping processes to meet the technical requirements of different cable types.

Common Functions and Core Performance of Cable Extrusion Line

All equipment within the Cable Extrusion Line category is designed around several shared functional and technical characteristics:

-

Continuous and stable extrusion of thermoplastic or fluoropolymer materials

-

Accurate control of insulation or sheath thickness

-

Compatibility with single-core and multi-core cable structures

-

High concentricity and smooth surface finish

-

Adaptability to different conductor materials and diameters

From a system perspective, a Cable Extrusion Line ensures consistency from batch to batch, helping manufacturers meet international standards for electrical, mechanical, and environmental performance.

Working Principle of a Cable Extrusion Line

The working principle of a Cable Extrusion Line is based on thermoplastic material melting, pressurization, and shaping:

-

Material Feeding

Plastic granules or powders (such as PVC, PE, XLPE, FEP, PTFE) are fed into the extruder through a hopper. -

Melting and Plasticization

Inside the extruder barrel, the rotating screw conveys, compresses, and melts the material using controlled temperature zones. -

Extrusion Forming

The molten material is pushed through a crosshead die, where it is evenly coated onto the conductor or cable core. -

Cooling and Shaping

The extruded cable passes through a cooling trough (water or vacuum type) to solidify the insulation or jacket. -

Diameter Control and Haul-off

Laser diameter measurement and traction units maintain dimensional stability. -

Take-up or Coiling

The finished cable is wound onto reels or drums for downstream processing.

This principle applies consistently across different types of Cable Extrusion Line systems, with variations depending on material and cable structure.

Main Types of Cable Extrusion Line

Cable Extrusion Line systems can be classified based on material type, application, and structural design. The table below presents a professional comparison.

Cable Extrusion Line Types and Characteristics

| Extrusion Line Type | Working Principle | Typical Materials | Key Applications |

|---|---|---|---|

| Core Insulation Extrusion Line | Single-layer insulation applied directly to conductor | PVC, PE, XLPE | Power cables, control cables |

| Sheath / Jacket Extrusion Line | Outer protective layer extrusion over cable core | PVC, LSZH, TPU | Industrial cables, building wires |

| Teflon Extrusion Line | High-temperature extrusion with precision screw design | PTFE, FEP, PFA | Data cables, aerospace, high-frequency cables |

| Foam Extrusion Line (Physical/Chemical) | Microcellular foaming to reduce dielectric constant | PE foam, FEP foam | Communication cables, coaxial cables |

| High-Speed Extrusion Line | Optimized cooling and traction for increased output | PVC, PE | Automotive cables, mass production |

Jiangsu Newtopp Precision Machinery Co., Ltd. develops multiple Cable Extrusion Line configurations, including Teflon extruders, core and jacket extruders, and chemical or physical foam extrusion systems, enabling compatibility with a wide spectrum of cable products.

Typical Application Scenarios

Cable Extrusion Line systems are widely used across various cable industries:

-

Power Cable Manufacturing

Insulation and sheath extrusion for low-voltage and medium-voltage cables -

Data and Communication Cables

Precise extrusion for signal integrity and dimensional stability -

Automotive and Robotic Cables

High-flexibility jacket extrusion with abrasion resistance -

New Energy Cables

Extrusion for charging cables, photovoltaic cables, and energy storage systems -

Industrial Control Cables

Multi-layer extrusion combined with stranding and taping processes

In practical production lines, Cable Extrusion Line equipment is often combined with stranding machines and taping machines to form a complete cable manufacturing solution.

Cable Extrusion Line vs Other Cable Manufacturing Equipment

To help users better understand the role of this category, the following comparison clarifies functional differences.

| Equipment Category | Main Function | Position in Process |

|---|---|---|

| Cable Extrusion Line | Apply insulation or sheath | Core forming stage |

| Cable Stranding Machine | Twist conductors together | Conductor preparation |

| Cable Taping Machine | Apply insulation or shielding tape | Intermediate protection |

| Take-up / Rewinding Machine | Collect finished cable | Final stage |

This comparison shows that the Cable Extrusion Line is the decisive stage where electrical insulation and mechanical protection are formed.

Integration with Complete Cable Production Lines

In modern factories, a Cable Extrusion Line is rarely operated in isolation. Jiangsu Newtopp Precision Machinery Co., Ltd. designs extrusion systems that integrate smoothly with:

-

Cage-type and tubular stranding machines

-

CNC vertical and horizontal taping machines

-

Automated diameter measurement and IoT monitoring systems

This integrated approach improves line stability and reduces production interruptions.

Frequently Asked Questions (FAQ)

Q1: What materials can a Cable Extrusion Line process?

A Cable Extrusion Line can process PVC, PE, XLPE, LSZH, TPU, and fluoropolymers such as PTFE and FEP, depending on extruder configuration.

Q2: How is extrusion thickness controlled?

Thickness is controlled through die design, screw speed, line speed, and real-time diameter measurement systems.

Q3: Can one Cable Extrusion Line handle multiple cable types?

With adjustable tooling and modular design, one Cable Extrusion Line can be adapted for different cable diameters and structures.

Q4: What factors affect extrusion quality?

Material quality, temperature stability, screw design, cooling efficiency, and traction synchronization all influence final cable quality.

English

English русский

русский Español

Español