Extrusion Line

Extrusion lines are a common and fundamental continuous production system in modern industry. Their core mission is to shape a specific raw material, typically a thermoplastic, into a long, uniformly shaped product through a continuous process. Imagine its operating principle as similar to the familiar extrusion process: the raw material, whether in granular, powdered, or preformed form, is first steadily fed into the front end of the system. There, intense mechanical shear forces combined with precisely controlled heat cause the material to undergo a softening-plasticization transition, becoming more fluid. This viscous stream is then forcefully pushed through a precisely designed forming die. The shape of the die's pores determines the cross-section of the final product, much like dough being squeezed through a pastry nozzle to create various shapes. While the hot, shaped product emerges from the die, it is still unstable and soft. Next, it enters a carefully designed cooling stage, where the temperature rapidly decreases through contact or environmental influences, allowing the shape and internal structure to solidify. Finally, these cooled and shaped continuous profiles are smoothly pulled out by subsequent pulling devices and, depending on the needs of the end use, cut or otherwise processed into the required length or coiled. The entire process, from raw material input to finished product output, is typically highly automated, efficient, and continuous, forming an indispensable industrial foundation for the manufacture of various plastic, rubber, and even some metal products with consistent cross-sectional characteristics.

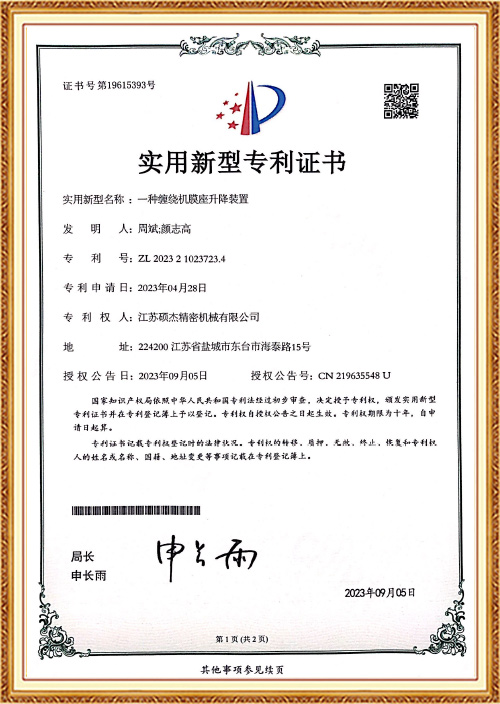

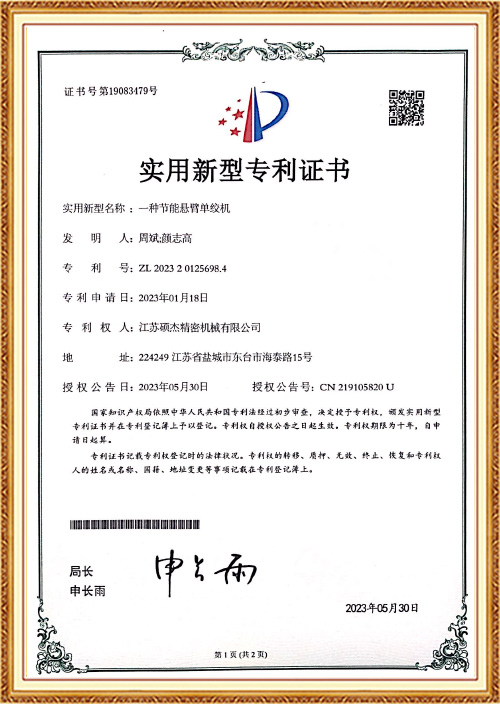

Since its establishment in 2004, Jiangsu Newtopp Precision Machinery Co., Ltd. has specialized in the research, development, design, and manufacturing of high-end cable equipment. After more than a decade of development and continuous effort, our company has grown to encompass three manufacturing plants, an IoT technology company, and the Kunshan Newtopp branch.

Newtopp Precision is a National High-Tech Enterprise and has obtained ISO9001 quality certification and ISO14001 environmental management system certification. Covering 50 acres, the company boasts an independent R&D center, a finishing center, and a paint booth, integrating R&D, design, manufacturing, and sales. We are committed to providing customers with high-quality products and excellent service.

Our company's sustainable development along the way is inseparable from the support and trust of our customers. The large enterprises have long-term cooperation with many customers from all walks of life.

-

NewTopp in 15th Shanghai International Wire and Cable ExhibitionNewTopp is not listed as an exhibitor in search results for the 15th Shanghai International Wire and Cable Exhibition (wire C...

-

What is the Core Process of a Teflon Wire Extruder?The core process for a Teflon wire extruder involves paste/powder extrusion, which consists of mixing the Teflon resin with a...

-

Troubleshooting and Solutions for the Wire Extruder Machine.Cable extrusion is a critical process in the manufacturing industry. It's the backbone of producing high-quality cables used ...

-

What are the latest innovations in cable extrusion machines?Here are notable recent innovations in cable extrusion machine technology, reflecting current industry advancements:1. Energy...

English

English русский

русский Español

Español