Cable Stranding Machine is a key piece of equipment in the wire and cable manufacturing industry, designed to combine multiple wires or conductors into a single, cohesive strand. This machine is widely used across various types of cable production, including power cables, communication cables, and specialty cables, providing consistent twisting and precise alignment of individual wires. The core functions of a Cable Stranding Machine include controlling the twisting tension, synchronizing rotation speeds, and maintaining uniform strand geometry, which are essential for ensuring product reliability and electrical performance. Modern cable stranding machines feature high-efficiency drive systems, advanced tension control mechanisms, and modular designs that allow easy adjustment for different wire sizes and strand configurations. These machines contribute to optimized production efficiency, reduced material waste, and improved cable quality. By integrating a Cable Stranding Machine into a cable manufacturing line, manufacturers can achieve stable performance, high precision, and adaptability for diverse production requirements.

Industrial Cable Production Ancillary Equipment Manufacturer

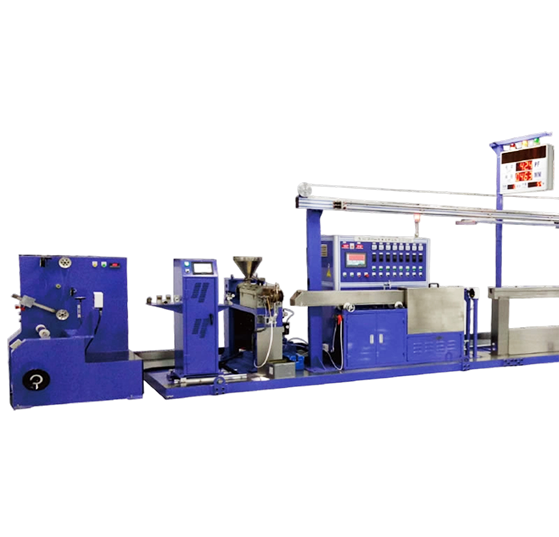

Cable Extrusion Line

Cable Extrusion Line is a specialized production system widely used in the manufacturing of electrical wires and cables. This line integrates multiple processes, including extrusion, cooling, and sizing, to produce insulated cables with consistent quality and precise dimensions. Cable Extrusion Line products are designed to handle various cable types, including power cables, communication cables, and control wires, making them suitable for diverse industrial applications. Key features of this category include high production efficiency, uniform insulation thickness, and compatibility with different raw materials such as PVC, PE, and XLPE. By streamlining the extrusion process and ensuring accurate control over cable dimensions, the Cable Extrusion Line supports continuous production, reduces material waste, and maintains the electrical performance of the finished cables.

Cable Taping Machine

Cable Taping Machine is a specialized equipment designed for the electrical and cable manufacturing industry, primarily used for wrapping insulating or protective tape around various types of cables. This category of machines focuses on precise tape application, uniform coverage, and high-speed operation, ensuring consistent insulation and protection of cable cores. Cable Taping Machines are commonly employed in both single-core and multi-core cable production lines, integrating seamlessly with extrusion, stranding, and sheathing processes. Key features of this category include adjustable tension control, automatic feeding systems, and compatibility with different tape materials, which allow manufacturers to meet diverse production standards. By using a Cable Taping Machine, companies can enhance production efficiency, maintain product quality, and achieve reliable cable insulation across a wide range of applications.

-

Phone

+86 188 2296 5630 +86-(0)515-8510 8601Email

[email protected]Address

No. 168 Haitai Road, Dongtai City, Jiangsu Province, China

English

English русский

русский Español

Español